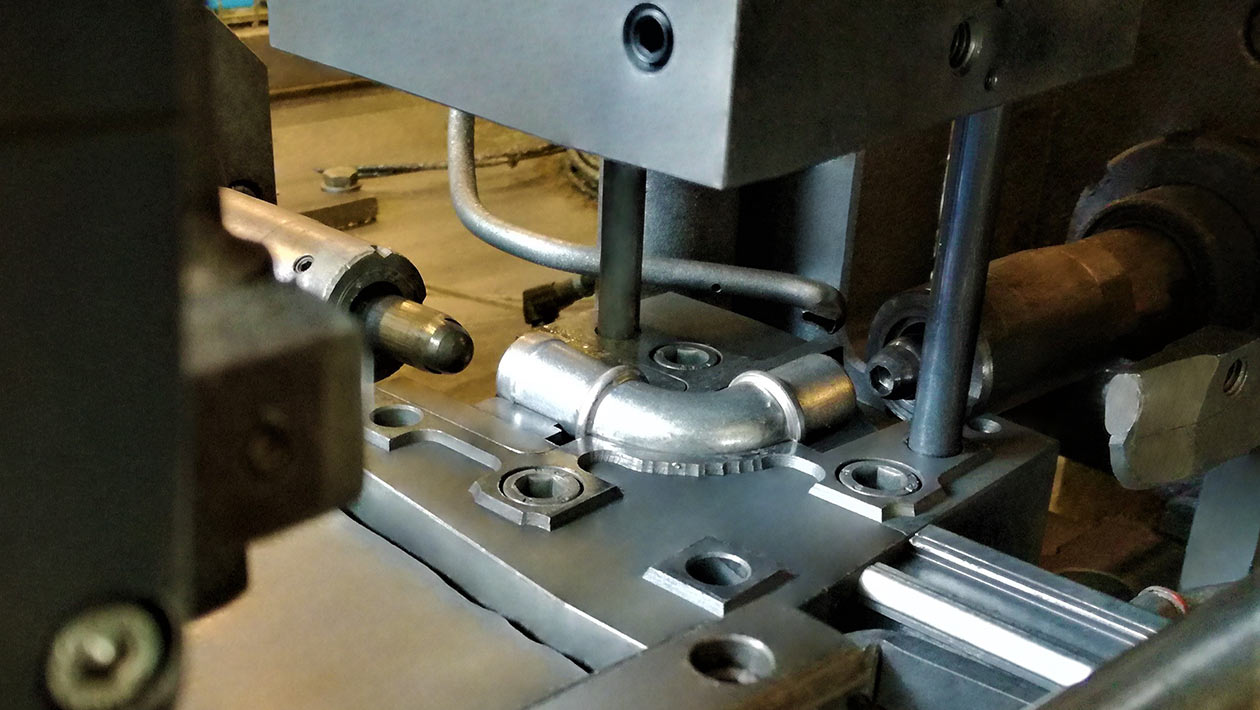

Metrology room

To guarantee each customer with the supply of certified metal pipes, we have the best equipment and accurate measuring instruments such as: 3D probe, optical profile viewer, surface roughness test, electronic microscope and various bench instruments to perform controls on shaped pipes. Furthermore, we have a metrology room where tests and conrols are carried out by our qualified staff in a controlled environment. We accompany the customer from the Prototype and PPAP phase to the management of any problem using specific methodologies such as 8D, Ishikawa Diagram and 5 WHIS. We industrialize the bent tubes starting from the process Flow Chart, we analyze the potential product and process defects before they occur with related FMEAs. We define Control Plans which we strictly implement in order to prevent non-conformties to reach the customer.

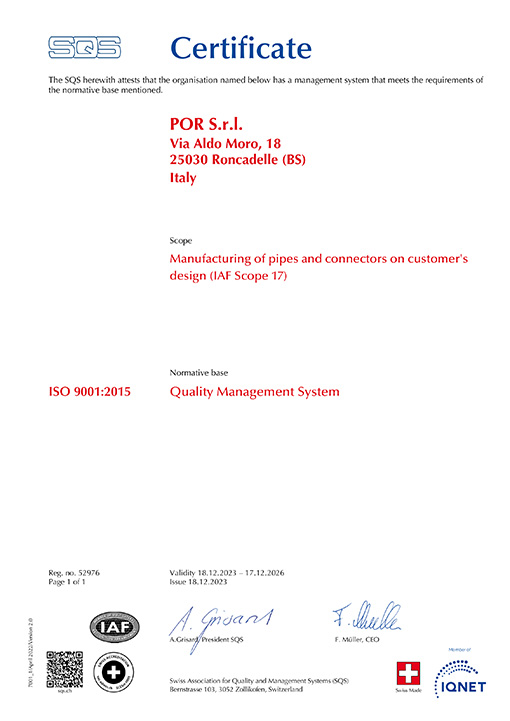

Certifications

There is only one rule to produce well: follow the rules. Por Srl boasts since 1997 a Company Quality System according to the ISO 9001 standard. We guarantee the conformity of the product starting from the materials, components and treatments, strictly controlled during the arrival acceptance phase and purchased only from qualified suppliers. The purchased materials are also subjected to continuous monitoring to guarantee the customer with top quality services.

Lot traceability

To further guarantee the quality of the products we manufacture, we provide the customer with production batch’s sheets that ensure the most precise traceability of the materials, components and products we use.

Request more information

Send us an email using our contact form to request a quotation or more information about our services.